With so many meals leaving restaurants by customer pickup and delivery drivers, one might think the pandemic has launched a gold rush of restaurant brands upgrading off-premises shelving to heated, frozen and cooled solutions. But not according to one leading manufacturer, who says the dwell time problem is typically best solved with better packaging and a more streamlined kitchen.

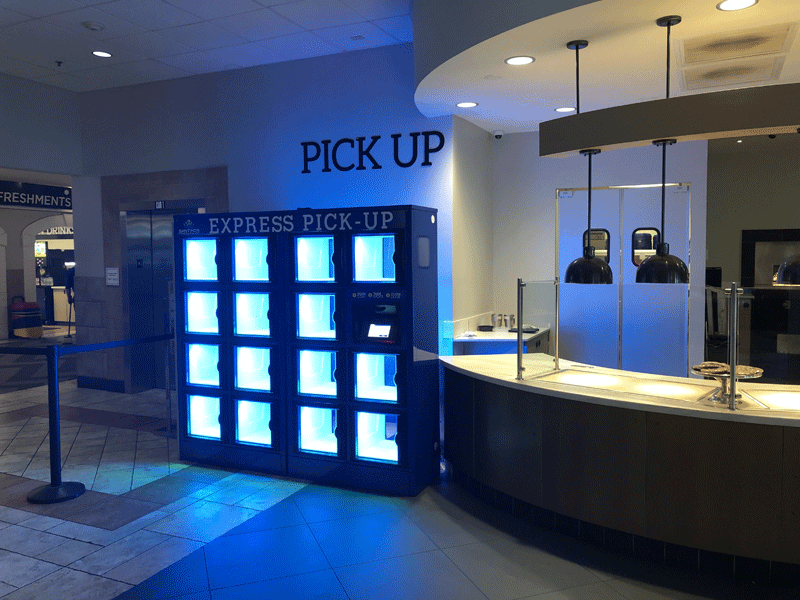

This “less is more” approach—from a manufacturer of smart shelves that can text customers when their food is ready, no less—is at odds with Apex Order Technologies’ recent acquisition of Brightloom’s intellectual property that transforms workaday pickup shelves into animated, brightly colored affairs.

While takeout and delivery shelving is undoubtedly getting more high tech in the future, the company stresses that restaurants should not overspend on frills like active heating or cooling, when better packaging and fully integrated ordering systems can minimize the amount of time a given meal sits on a shelf while awaiting its delivery driver or the hungry hands of a takeout customer.

Apex CEO Mike Wills

“The thing that surprised us after COVID-19 was the ferocity in which they came at us—it even exceeded our expectations,” said Apex CEO Mike Wills, who noted that his salesforce has become de facto consultants for restaurants looking for a better solution. “Those early-stage folks who are now suddenly going from an interest level of 2 to 10 overnight, they don’t know what they don’t know, so they’re asking questions all over the map.”

Since most restaurants weren’t originally designed for such high volumes of delivery and carryout business, the pre-pandemic delivery rush forced a lot of restaurants to add dedicated shelving so drivers and takeout-ers weren’t getting in the way of the cashier or front-of-the-house guest flow.

With COVID pouring gasoline on this situation, a restaurant supplier arms race is on to provide more sophisticated shelving that can include a customer’s name, restaurant branding, limited-time offers and, yes, in some cases, animated video screens or heating or cooling elements. Even so, Wills said his team is often talking restaurant operators off a ledge, before plunging in with expensive temperature control equipment that, of course, includes ongoing maintenance.

“The amount of money investment that you have to put into a heated solution far outstrips the return on investment if you can hone your processes, so that by the time you load that order in the appropriate packaging to keep that order within a relative quality zone for a period of five to seven minutes, I can guarantee you those people will be there picking up those orders and it will be as fresh or fresher than, god bless them, DoorDash delivery guys, Uber Eats and the rest of them,” he added.

To keep an eye on the customer side of the equation, Wills orders delivery at least three times a week, and remains “fascinated” that so many orders arrive in a plastic or paper bag, at best.

“The dwell time in most of these QSRs and fast-casual restaurants … is measured in a handful of minutes, so the whole concept of heated, chilled, frozen, it’s a moot point,” he said. “Ambient with rapid volume through there is the best solution.”

At the extreme, highest-volume end of the spectrum, Apex has found that university cafeterias and dorms with automatic “food’s ready” notifications can have dwell times that are measured in just one or two minutes, illustrating the benefit of a high-volume operation where the end user or driver is kept apprised of the food’s status.

Inside the restaurant, software integration is another important part of the equation, removing the need for manual order entry and human-based errors that are inherent in any bucket brigade-type operation.

Especially with the largest brands, Wills said that taking a consultative approach to shelving can butt up against executives or management teams hell bent on springing for all the bells and whistles, which often gives Apex a chance to set up a pilot project to prove its thesis that so-called ambient shelves are often the most cost-effective solution.

Asked about rumblings that the federal government might seek to extend food safety regulations to the actual delivery trip, Wills said he’s heard such rumors, but isn’t anticipating any forthcoming, nationwide regulation.

After scooping up the remnants of Eatsa, which morphed into Brightloom before the acquisition, it’s a safe bet that video capability will be rolling out to an increasing number of shelving units, further streamlining restaurant operations by identifying a dwelling meal’s one, true owner, while eliminating the propensity for customers to rifle through the bags, which has obvious health implications amid the pandemic.

“They had a pretty sizable pile of intellectual property, a lot of bleeding-edge designs in terms of contactless cubbies,” Wills added of Brightloom. “We found, not from every brand but a sizable enough of them, that said, hey, wouldn’t it be cool if I could use the device itself to promote digital, time-based campaigns, seasonal campaigns, BOGO offers, whatever, which could stimulate additional consumer spending.”

Having used the formerly known-as-Eatsa shelving units at a Wow Bao in downtown Chicago, where just one bouncer-like employee guides you through the do-it-yourself ordering process, the dancing animations and clear name identification made for a more modern, amusing experience. While accuracy and safety are the cornerstones, this reporter isn’t turning down a pleasant greeting, no matter how digitized the source.