There are plenty of adages that remind us what we know today may not apply tomorrow. That’s true in restaurant technology and especially restaurant robotics, as SJW founder and CEO Nipun Sharma has learned.

Before becoming an investor and mentor, his whole career was in restaurants, with a special proclivity for operating steakhouses and fine dining. When he started working on a new project with automation in mind, he found a lot of action, but not exactly what he wanted or what was promising but very early stage.

He found a lot of firms were automating away one or two tasks. Even highly automated restaurants were still plagued by “legacy problems” like high rent and staffing challenges. Sharma said he wanted to untether great food from those systemic problems.

Instead of buying a solution, Sharma co-founded SJW Robotics to develop what he wanted with help from robotic experts and food safety gurus to build his dream automated restaurant. But first he had some unlearning to do.

“We thought making an existing restaurant kitchen better is going to shift the needle, but I think we needed to start from scratch,” said Sharma. “When we started, I said, ‘Everything I know is wrong.'”

Instead of automating away a task or two in an existing kitchen, he built with the same mindset Picnic, Nommi and Hyper Robotics used to tackle the pizza segment: dump in ingredients, and output prepared or semi-prepared food. It doesn’t have quite the same wow-factor as robotic arms or the automation theater of a brand like Spyce, in San Francisco, but Sharma said that novelty doesn’t really matter.

“We’re in the food selling business, nobody cares who makes their food. If it’s good, I’ll pay for it and if it’s great, I’ll only come to you,” said Sharma. “I don’t care about the sophistication of the robotics.”

The outcome was still pretty sophisticated, comprised of a handful of novel patents and a lot of new restaurant robotics ideas. It’s a SUV-sized kiosk dubbed the RoWok, or robotic wok. Inside the futuristic-looking box, there are 16 ingredient “silos,” capacity for 10 sauces as well as oil and liquid egg. In all, there’s capacity for 350 to 400 meals when fully loaded, at a rate of 60 meals per hour.

As might be apparent, Sharma and the team opted to tackle Asian cuisine first.

“Asian cuisine is the most complicated food, we did that first,” said Sharma. “From here on, anything else is easy. It’s ready for Italian food and Indian food. It’ll take a couple updates to integrate Mexican and Greek.”

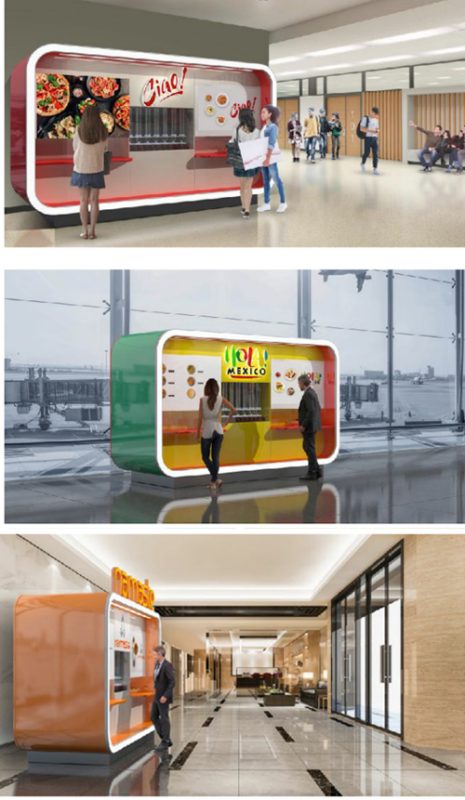

A few examples of different brands in the same kiosk format.

While he took the kitchen and the dining room out of the equation, Sharma said he was careful to build something with the food supply chain in mind so the big-name providers like US Foods or Sysco could deliver standard ingredients for use in the automated kiosk. Sliced carrots in a bag or pre-marinated chicken can go directly in from the food delivery truck

“I looked at myself as a franchisor, so the input needs to be the same as any concept,” said Sharma, noting HMSHost, a pilot partner, as an ideal target. “HMS and others already have a presence there, they don’t have to reinvent the wheel. They have the refrigerator, the supply chain. For them, all the food is worked out, it’s just a question of taking a few hours a day to refill.”

There are some other perks, deep customization is possible without annoying the non-existent staff. There are some AI and machine learning tricks, as well. For example, if the kiosk has chicken about to expire, it can automatically offer discounted chicken dishes.

He said he also designed it to be brand agnostic, while he wanted to develop his own brands, well-known brands were a big draw for potential clients like airports, grocery stores and other institutional foodservice providers.

On the business side, Sharma said the kiosk slashes efficiencies that he claims eat up about 50 percent of cashflows. There’s minimal labor to load and maintain the machine, 100 square feet of space and no need for a hood, grease trap or other traditional high-dollar restaurant infrastructure investments. That means the cost of a bowl can be less or margins can be higher.

The $250,000 price tag can be repaid in two to two and a half years, compared to the average restaurant payback period of seven years.

SJW Robotics is currently raising $5 million to roll out more devices with a goal of 2,000 units out in the wild in the next five years and $1 billion in sales. Currently, there is one device in operation and four or five set to be installed in the next few months.